Many quality control (QC) processes in clinical laboratories are now automated. These high-throughput automated instruments include internal controls that, if they fail, will stop patient specimens from being analyzed. Laboratories also perform external controls and carefully monitor them for trends. Mass spectrometry assays require the same level of—or arguably more—quality review. However, the instrumentation, work flows, and data are much more complex and not as amenable to automated review. When mass spectrometry entered the clinical laboratory, it lacked automated processes including sample preparation, data processing, data review, and result verification in the laboratory information system (LIS).

Over time, well-resourced clinical labs and commercial vendors have created solutions for automating sample preparation with liquid handlers and subsequently interfacing results with the LIS. However, until recently the same time and energy has not gone toward developing solutions for automated data/quality review for mass spectrometry assays. Best practice guidelines and College of American Pathologists accreditation checklists recommend or require monitoring several parameters in addition to the traditional QC values. These include signal-to-noise (S/N) ratios of blank and double blank samples, retention time, ion ratios, S/N ratios of patient samples, and peak areas of internal standards. Many mass spectrometry assays are designed to measure multiple analytes simultaneously, resulting in hundreds of data points per patient specimen. Without automated software tools, result preparation requires many manual processes and decision-making steps that add up to extensive technologist time.

A Cost/Benefit Analysis of Automated QC

As with all technology assessments in the clinical laboratory, laboratorians should carefully weigh the benefits and costs of implementation. There are numerous benefits to implementing automated QC approaches for mass spectrometry. From a patient safety perspective, automating key portions of the mass spectrometry workflow can mitigate the risk of errors from manual review. For example, weary staff might miss a peak detection and integration that software did not detect appropriately, leading to a false negative result downstream. Decreasing the amount of time spent performing manual review can significantly decrease the total cost of performing the assay, depending on the overall proportion of labor costs. From a quality standpoint, automated techniques help better standardize the assay performance by decreasing the variation observed between technologists. Finally, many manual review activities require repetitive mental work, so automated approaches shift technologist tasks from these less engaging activities to higher level cognitive activities, such as analyzing data from multiple analytes and multiple patients in a batch to assess quality.

Because mass spectrometry is a specialized market within the clinical lab product space, there are limited commercial options for automated QC and as a result, fewer competitive forces to drive pricing. Vendors independent of instrumentation manufacturers such as Indigo Bioautomation provide considerable automation and streamlining of data review. As clinical applications of mass spectrometry have matured, instrument vendors also have incorporated and streamlined more relevant QC checking functionality. It is important to understand the pricing model for these products, however, because they may be cost-effective in a larger reference laboratory setting but make less financial sense for labs with lower throughput.

Is Building a Custom Solution an Option?

An alternative to purchasing commercial products is to develop a custom solution either in-house or in collaboration with a custom software vendor. Developing software in-house requires specialized staff and resources but is within reach for some laboratories which have invested in developing internal software programming competency. Because most technologists and directors might not understand all the benefits custom software provides, explaining the data analysis needs to either in-house programming staff or to vendor programmers takes a considerable amount of time.

Overall, the up-front cost of a custom solution may look more attractive than specialized vendor solutions on the market, but it is important to keep software maintenance costs in mind. Instruments and procedures may change, requiring software modifications that can be estimated conservatively and factored into the total cost. A rule of thumb that many software vendors abide by is that the maintenance cost should be budgeted yearly as 20% of the initial product cost.

The University of Washington Department of Laboratory Medicine developed a custom software solution to support a unique workflow for our liquid chromatography mass spectrometry opiate assay that required multiple dilutions and spiked aliquots per patient sample (Clin Chim Acta 2013;415:290–4). At the time of development, vendor software was not available to support the workflow, which required both routine checks (e.g. S/N ratio, retention time, ion ratio) and logical tests comparing multiple dilutions and spikes with one another. While the in-house solution did not completely replace manual data review (manual assessment of chromatography was still required), the program significantly decreased the amount of technologist time for this assay by more than 50% and is still used today to ensure accurate results.

How Do I Justify the Cost to My Department and Institution?

The first step is to know your institution’s culture and frame the request accordingly. For example, while cost is almost always a consideration, some institutions also weigh it equally with patient safety, improvements in delivery (e.g. turnaround time), and reduction in waste. Metric-driven organizations might require baseline data and estimated improvement goals for a variety of measures.

For a resource request, consider gathering data on annual volume of tests that would be impacted, current tech time dedicated to data review, projected tech time saved with an automated review process, and the number of errors/deviations in tech decisions. It also helps to draft an implementation plan with a timeline in order to identify which hospital departments might be affected in addition to the laboratory (information technology, facilities, etc.).

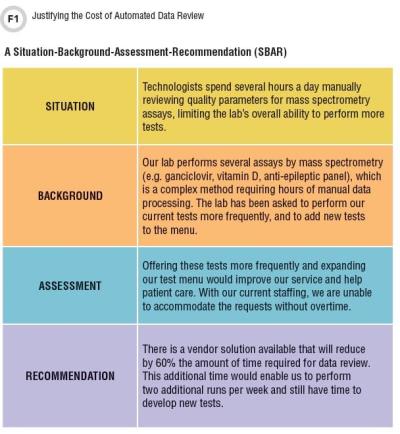

Communicating the need effectively is just as important as your comprehensive analysis of the proposed solution and any demonstrated financial gain. One such communication tool is the SBAR (Situation-Background-Assessment-Recommendation), shown in Figure 1.

As more of us welcome mass spectrometry into our laboratories, we will see an increasing need for tools to automate the quality review process—tools that, preferably, will not break the bank.

CLN's Focus on Mass Spectrometry is sponsored by Waters Corporation.