Each year, 12 million people in the United States receive the wrong diagnosis from outpatient clinics (1). Over 7.5 billion lab tests are performed in the U.S. annually, and 80 percent of clinical decisions are made based on laboratory testing (2). However, a core issue of misdiagnoses that often goes undetected is device materials.

While several components make up a medical device, it’s imperative that the materials used are pure and meet the highest quality standards. There is an inherent level of trust in devices used in clinical and laboratory settings that, if operated correctly, they will yield accurate results. However, there is no certainty that samples are kept safe and uncontaminated throughout analysis.

Regardless of the experience of a medical or laboratory professional or how meticulous they are with equipment, if the materials are ineffective, the test results are potentially unreliable. A diagnosis can be life-changing and for practitioners and patients relying on pathology examinations, it is imperative that a reliable result is provided. An inaccurate diagnosis can cause patients to believe they are ill and undergo unnecessary treatments. The impact of inaccurate results can also result in additional operational costs for laboratories and liabilities from patients who suffer greatly.

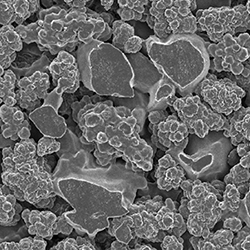

This is where new Certified Pure Porex products play a crucial role in guaranteeing that materials used in devices do not interfere with a diagnosis. A recent independent study conducted for Porex on a set of expanded offerings in the Certified Pure Porex product lineup found that the media and filters have virtually no material additives, contaminates or heavy metals that can cause interferences in clinical, analytical and blood transfusion testing. Certified Pure Porex materials were tested by the ASTM F21012 Standard, which sanctions higher standards for better performance, and was found to have over 99.99978 percent aerosol bacterial filtration efficiency (BFE), offering a nearly perfect resistance against the material being contaminated by bacteria. The testing procedure severely challenges most filtration materials and allows a reproducible bacterial experiment. Additionally, the components underwent tests confirming ISO 10993-4 and 10993-5 biocompatibility testing regulatory compliance as well as ICP-MS, an analytical testing method with high sensitivity and, as a result, accuracy.

For the study, Porex expanded its Certified Pure Porex program to include bonded fiber and sintered particles, as well as the award-winning Fortress pipette tip filters, to help provide more secure, reliable testing results and outcomes for liquid handling applications. With liquid handling ranking as one of the most common laboratory operations, cross-contamination is a primary concern while handling a wide variety of routine and infectious samples. Most laboratory contaminants are caused by aerosols, making the prevention of aerosol entry into equipment and samples paramount. This is especially critical in circumstances where it is necessary to work with infectious disease pathogens.

Each year, there are more than 13.2 million donors in the United States (3), who are screened for risk of disease pathogens. Blood samples used for diagnosis or life-saving donations used with ill-equipped devices can potentially harm patients and healthcare workers as well as threaten the critical blood supply.

While the study found that the Fortress pipette filters contain no material additives, the innovative technology also provides a higher level of cleanliness for all laboratory tests, restores confidence in reliable sample analysis and allows for pure sample recovery.

Pipettes are typically subject to easy interference and can subsequently compromise the sample contained within the device from a myriad of sources as over-pipetting or using filter pipette tips with non-pure filters or other materials. The Porex Fortress pipette tip filter incorporates inert and hydrophobic filters that function as a barrier to seal out unwanted fluids and aerosols, keeping them from infiltrating the pipette shaft to address this concern.

The filter protects samples from aerosols that could be preexisting in the pipette from previous procedures, as well as those that are created when the sample liquids are aspirated. The innovative filter provides this protection while simultaneously optimizing airflow and allowing for sample recovery, thus helping to enhance the accuracy of the procedure.

Porex is the first company to rigorously test its porous polymeric materials, used in critical clinical, diagnostic and medical applications, through an extensive qualification program conducted by nationally renowned third-party laboratories. The company sought these extra measures to ensure the safety of components in direct contact with patient samples during common procedures such as those in blood transfusion medicine. Porex originally initiated the Certified Pure Program in 2009 by qualifying its porous polymeric materials through analytical, clinical and life sciences testing procedures.

For industry manufacturers including pharmaceutical companies undergoing expensive FDA-approved clinical trials, the third-party verification of Certified Pure Porex media and filters can grant peace of mind that virtually no test instruments will negatively impact outcomes. Preventing compromised results is the most cost-effective activity to ensure the integrity of data collection. Certified Pure Porex components proactively preserve the efficacy of results that, when jeopardized, can lead to expensive repercussions.

To learn more about Porex’s Certified Pure Porex program visit www.porex.com.

1. https://qualitysafety.bmj.com/content/23/9/727

2. https://www.grandviewresearch.com/industry-analysis/in-vitro-diagnostics-ivd-quality-control-market

3. https://www.cdc.gov/bloodsafety/basics.html

Industry Insights articles are created and paid for by advertisers. The views expressed in these articles do not necessarily represent AACC’s views, and their inclusion in CLN is not an endorsement by CLN or AACC.